Industrial Polymers: 7 Essential Benefits of Using High-Quality Materials

February 23, 2025Introduction

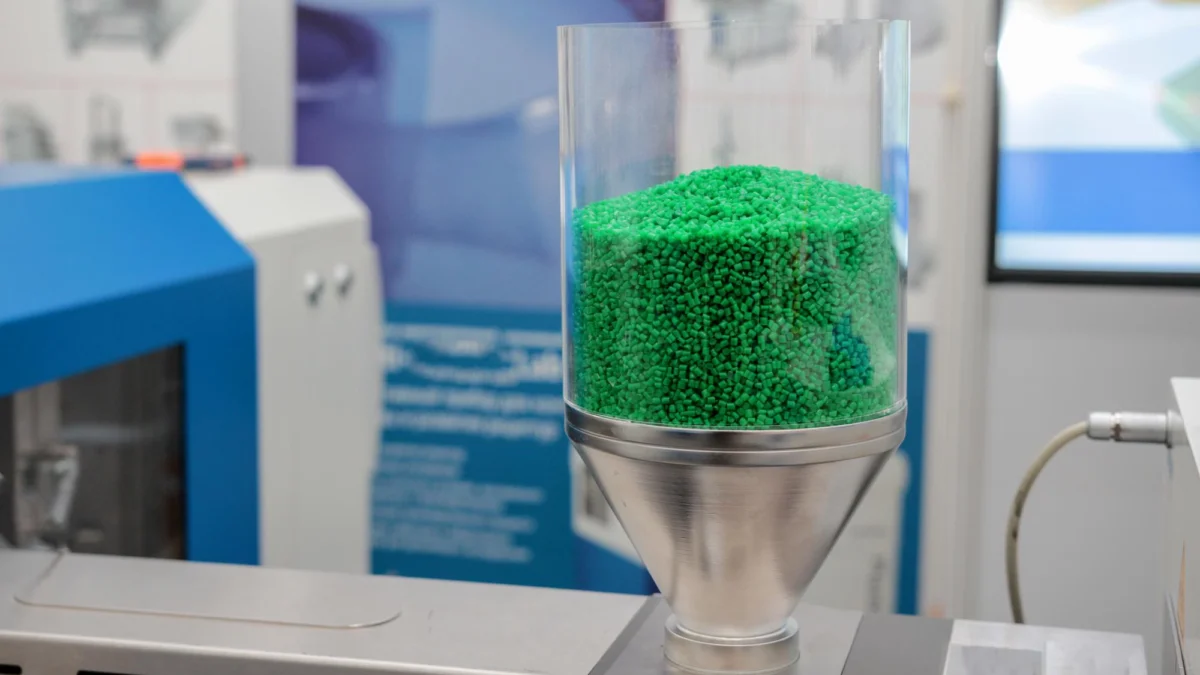

The advancement of Polymer compounds has significantly influenced modern manufacturing, offering enhanced mechanical, thermal, and chemical properties. These innovative substances are essential in industries such as automotive, packaging, electronics, and healthcare due to their ability to provide durability, flexibility, and sustainability. As industries continue to seek high-performance alternatives to traditional materials like metal and glass, these advanced formulations have become indispensable.

This article delves into the importance of Polymer compounds in manufacturing, their various applications, and the technological progress they drive.

What Are Polymer compounds?

Engineered material solutions are developed by combining a foundational substance with reinforcing agents, stabilizers, and performance enhancers to achieve specific characteristics. By modifying the composition, manufacturers can fine-tune mechanical strength, heat resistance, and chemical stability to meet the demands of different industries.

Unlike conventional materials, which often have fixed properties, these innovative blends offer a high degree of adaptability. Whether an application requires flame retardancy, impact resistance, or enhanced elasticity, custom formulations ensure the material performs optimally under various conditions.

Key Applications of Polymer compounds

1. Automotive Industry

The transportation sector has embraced these high-performance materials to improve vehicle efficiency, safety, and longevity. Their lightweight nature reduces overall vehicle mass, leading to better fuel economy and lower emissions.

Many critical components, such as bumpers, interior panels, and protective casings, benefit from advanced material technology. These substances also contribute to noise reduction inside vehicles and improve crash resistance, offering passengers greater protection. Furthermore, their resistance to extreme temperatures ensures that automotive parts maintain structural integrity over time.

2. Packaging Industry

The need for sustainable and efficient packaging solutions has driven the adoption of lightweight yet durable materials. In both flexible and rigid packaging, these substances offer superior barrier properties, helping to extend the shelf life of food and pharmaceutical products by protecting them from moisture, oxygen, and contaminants.

Additionally, the recyclability and biodegradability of newer formulations contribute to sustainability efforts, reducing plastic waste and promoting environmentally responsible manufacturing practices.

3. Electronics and Electrical Components

Modern electronics require materials that can withstand heat, resist electrical currents, and provide insulation. These advanced substances are found in circuit boards, wire coatings, and enclosures, helping to prevent electrical failures and ensuring device longevity.

In high-performance applications such as 5G networks, aerospace electronics, and industrial automation, materials with superior thermal stability and electromagnetic shielding properties are critical. Their role in increasing energy efficiency and minimizing electronic interference makes them a vital part of next-generation technology.

4. Medical and Healthcare Innovations

The healthcare industry depends on non-reactive and biocompatible materials for a wide range of applications, including prosthetics, surgical tools, medical tubing, and pharmaceutical packaging. These substances must meet stringent safety standards to ensure they do not cause adverse reactions when used inside the human body.

Recent developments have introduced antimicrobial surfaces and smart materials that respond to environmental conditions, further enhancing medical safety and effectiveness. Innovations in drug delivery systems also leverage these materials to create capsules and coatings that control the release of medication, improving patient outcomes.

5. Construction and Infrastructure

In building and infrastructure projects, durable and weather-resistant materials are essential for long-term structural integrity. These advanced materials are used in applications such as pipes, insulation panels, roofing sheets, and coatings, providing protection against corrosion, moisture, and extreme weather conditions.

Because they are lightweight yet highly durable, they also reduce construction time and transportation costs. Additionally, fire-retardant properties and resistance to harsh chemicals make them ideal for industrial and commercial building applications.

Advantages of Polymer compounds in Manufacturing

1. Superior Durability

These materials are engineered to withstand harsh conditions, including extreme temperatures, high impact, and corrosive environments, ensuring that products maintain their integrity over time.

2. Weight Reduction Benefits

Compared to conventional materials such as steel, aluminum, and glass, these alternatives offer significantly lower weight while maintaining strength. This reduction in weight helps improve energy efficiency in transportation and ease of handling in construction and manufacturing.

3. Cost Efficiency

The ability to achieve high performance at a lower cost than traditional materials makes these solutions attractive for manufacturers. Their ease of processing and long lifespan contribute to cost savings across industries.

4. Customization and Versatility

Different applications require specific material properties, and engineered blends can be tailored to meet exact industry needs. Whether for medical devices requiring biocompatibility or automotive parts needing heat resistance, these materials can be optimized accordingly.

5. Environmental Sustainability

As industries move toward eco-friendly practices, the development of biodegradable and recyclable alternatives plays a crucial role in reducing environmental impact. New innovations focus on reducing reliance on fossil-fuel-based inputs and increasing the use of renewable resources.

Future Innovations in Polymer compounds

With rapid advancements in research and technology, the future of Polymer compounds is focused on sustainability, smart functionality, and improved performance. Some of the key trends include:

- Biodegradable and Compostable Materials: Addressing the global plastic waste issue by developing alternatives that break down naturally.

- Self-Healing Materials: Capable of repairing minor damages, increasing product lifespan, and reducing maintenance costs.

- High-Performance Composites: Combining multiple materials to enhance strength, heat resistance, and weight reduction, benefiting industries like aerospace and transportation.

- Conductive and Smart Materials: Used in next-generation electronics, offering features such as temperature responsiveness, energy storage, and even self-adjusting insulation.

As these trends continue to evolve, the integration of these high-performance materials into everyday applications will drive new opportunities for efficiency, sustainability, and innovation across multiple industries.

Conclusion

The continuous development of Polymer compounds has reshaped manufacturing by providing sustainable, cost-effective, and high-performance solutions. Their adaptability ensures a broad range of applications, from automotive and healthcare to electronics and construction.

As industries push for greater efficiency and sustainability, these materials will play an even more crucial role in shaping the future. With ongoing research driving innovation, the possibilities for these materials continue to expand, leading to more efficient, resilient, and eco-friendly solutions for global manufacturing.